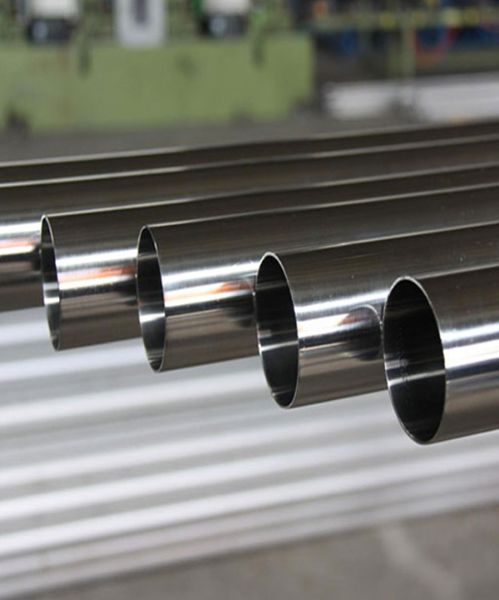

Stainless Steel 304 / 304L Pipes and Tubes

Supplier and Stockist

ASTM - A312/A213/A269/A358, UNS - S30400/S30403, DIN - 1.4301/1.4306 /1.4307

SS 304L Pipes Manufacturer, Stainless Steel 1.4306 Pipes / Tubes, Stainless Steel UNS S30403 Pipes, SS 304L Tubes Manufacturer, SS 304 Tubes Manufacturer, SS 304L Tubes Supplier, SS 304 Pipes Supplier, SS 304 Tubes Supplier, ANSI B36.19 SS 304L Pipes stockist, SS 304 Pipes manufacturer, SS 304L Pipes Supplier, SS 304L Tubes Stockist, 304 Stainless Steel Pipe Supplier, SS 304 Pipes stockist, SS 304 Tubes stockist, SS 304L Tubes Manufacturer in Mumbai, India.

Table Of Content

-

What is Stainless Steel 304 / 304L Pipes & TubesWhat is Stainless Steel 304 / 304L Pipes & Tubes

-

Stainless Steel 304 / 304L Pipes & Tubes SpecificationStainless Steel 304 / 304L Pipes & Tubes Specification

-

ASME SA 312 / SA 213 TP304/304L Pipe & Tubes Equivalent GradesASME SA 312 / SA 213 TP304/304L Pipe & Tubes Equivalent Grades

-

Stainless Steel 304 / 304L Pipes & Tubes StockStainless Steel 304 / 304L Pipes & Tubes Stock

-

SS 304 / 304L Pipes & Tubing Chemical CompositionSS 304 / 304L Pipes & Tubing Chemical Composition

-

Stainless Steel 304 / 304L Pipe & Tube Mechanical PropertiesStainless Steel 304 / 304L Pipe & Tube Mechanical Properties

-

Other Types of Stainless Steel 304 / 304L Pipes & TubesOther Types of Stainless Steel 304 / 304L Pipes & Tubes

-

SS 304 / 304L Pipes & Tubes Popular SearchesSS 304 / 304L Pipes & Tubes Popular Searches

-

Export Destinations For Stainless Steel 304 / 304L Pipes & TubesExport Destinations For Stainless Steel 304 / 304L Pipes & Tubes

-

Domestic Supply For Stainless Steel 304 / 304L Pipes & TubesDomestic Supply For Stainless Steel 304 / 304L Pipes & Tubes

Alloy stainless steel grade 304 is the austenitic stainless steel part of the T-300 SS series. The alloy is a mixture of Chromium and Nickel along with the addition of elements. This alloy is also called nickel and chromium austenitic alloy. SS 304 is less electrically and thermally conductive than carbon steel. It is essentially non-magnetic SS 304 Tubes has higher corrosion resistance than regular steel, and is widely used because of the ease with which it is formed into various shapes. The SS 304L has many good welding and forming attributes.

SS 304L Tubes Manufacturer, SS 304L Tubes Supplier, ASTM A312 SS 304L Tubes stockist, SS 304L Pipes Supplier, SS 304 Pipes Stockist, SS 304 Pipes Manufacturer, SS 304 Tubes Supplier, SS 304L Pipes manufacturer, SS 304L Tubes Stockist, SS 304 Tubes Manufacturer, SS 304 Tubes Stockist, SS 304L Pipes stockist, SS 304 Pipes Supplier in Mumbai, India.

These fittings are highly durable and are easily fabricable. The super finish and good machinability have made our Tubes and Pipes higher in demand. SS 304 L alloy is similar to 304 grade, but it has less carbon content and improved properties. Bhagyalaxmi Steel has established its manufacturing unit with the latest machinery and advanced tools to manufacture the best quality tubes. Our workforce efficiently applies the technology and tools to fabricate the special quality of SS 304 Pipes & Tubes.

All the offered range of Pipes and Tubes is tested on various parameters to avoid defects. We also perform tests like destructive and non-destructive tests to ensure the quality of Tubes. We also offer the required documentation along with good packaging for our ordered Pipes and Tubes. We understand the demand for quality and damage-proof packaging, and thus, we use good quality material for packing SS 304L Pipes & Tubes to prevent rust during transportation. We deliver our order in the minimum Period as we have a highly modernized logistics department. Therefore, all our offered range of Pipes and Tubes is available at reasonable rates.

Standard Specification For Stainless Steel 304 / 304L Pipes & Tubes

| Standards | ASTM / ASME A213, A249, A269, A312, A358 / SA213, SA249, SA269, SA312, SA358 |

| Outer Diameter | 6.00 mm OD up to 914.4 mm OD, Sizes up to 24” NB |

| Thickness | 0.3mm – 50 mm |

| Type | Seamless / ERW / EFW / Welded / Fabricated / LSAW Pipes |

| Schedule | SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS |

| Seamless Pipes & Tubes Size | 1 / 8″ NB – 24″ NB |

| ERW Pipes & Tubes Size | 1 / 8″ NB – 36″ NB |

| EFW Pipes & Tubes Size | 6″ NB – 100″ NB |

| Length | Single Random, Double Random & Required Length |

| Form | Round Pipes/Tubes, Square Pipes/Tubes, Rectangular Pipe/Tubes, Coiled Tubes, “U” Shape, Pan Cake Coils, Hydraulic Tubes |

| End | Plain End, Beveled End, Treaded |

SS 304 / 304L Pipes & Tubing Equivalent Grades

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| SS 304 | 1.4301 | S30400 | SUS 304 | 304S31 | 08Х18Н10 | Z7CN18‐09 | X5CrNi18-10 |

| SS 304L | 1.4306 / 1.4307 | S30403 | SUS 304L | 3304S11 | 03Х18Н11 | Z3CN18‐10 | X2CrNi18-9 / X2CrNi19-11 |

Types of Stainless Steel 304 / 304L Pipes and Tubes

Stainless Steel 304 / 304L Seamless Pipes

ASTM A312 Stainless Steel 304 / 304L Seamless Pipes, Stainless Steel 1.4301 Seamless Pipes, SS S30400 Seamless Round Pipes Stockist, SS S30403 Seamless Rectangular Pipes, SUS 304 Seamless Square Pipes, Stainless Steel 1.4306/1.4307 Seamless Piping, ASME SA312 TP304L Seamless Pipes Supplier in Mumbai, India.

Stainless Steel 304 / 304L Welded Pipes

ASTM A312 Stainless Steel 304 / 304L Welded Pipes, Stainless Steel 1.4301 Welded Rectangular Pipes, SS S30400 Welded Round Pipes Stockist, SS S30403 Welded Pipes, SUS 304 Welded Square Pipes, Stainless Steel 1.4306/1.4307 Welded Piping, ASME SA312 TP304L Welded Pipes Supplier in Mumbai, India.

Stainless Steel 304 / 304L ERW Pipes

ASTM A312 Stainless Steel 304 / 304L ERW Pipes, Stainless Steel 1.4301 ERW Pipes, SS S30400 ERW Pipes Stockist, SS S30403 ERW Pipes, SUS 304 Electric Resistance Welded Pipes, Stainless Steel 1.4306/1.4307 ERW Piping, ASME SA312 TP304L ERW Pipes Supplier in Mumbai, India.

Stainless Steel 304 / 304L EFW Pipes

ASTM A358 Stainless Steel 304 / 304L EFW Pipes, Stainless Steel 1.4301 EFW Pipes, SS S30400 EFW Pipes Stockist, SS S30403 EFW Pipes, SUS 304 Electric Fusion Welding Pipes, Stainless Steel 1.4306/1.4307 EFW Piping, ASME SA358 TP304L EFW Pipes Supplier in Mumbai, India.

Stainless Steel 304 / 304L Seamless Tubes

ASTM A213 Stainless Steel 304 / 304L Seamless Tubes, Stainless Steel 1.4301 Seamless Tubes, SS S30400 Seamless Tubes Stockist, SS S30403 Seamless Tubes, SUS 304 Seamless Tubes, Stainless Steel 1.4306/1.4307 Seamless Tubing, ASME SA213 TP304L Seamless Tubes Supplier in Mumbai, India.

Stainless Steel 304 / 304L Welded Tubes

ASTM A269 Stainless Steel 304 / 304L Welded Tubes, Stainless Steel 1.4301 Welded Tubes, SS S30400 Welded Tubes Stockist, SS S30403 Welded Tubes, SUS 304 Welded Tubes, Stainless Steel 1.4306/1.4307 Welded Tubing, ASME SA269 TP304L Welded Tubes Supplier in Mumbai, India.

Stainless Steel 304 / 304L ERW Tubes

ASTM A269 Stainless Steel 304 / 304L ERW Tubes, Stainless Steel 1.4301 ERW Tubes, SS S30400 ERW Tubes Stockist, SS S30403 ERW Tubes, SUS 304 Electric Resistance Welded Tubes, Stainless Steel 1.4306/1.4307 ERW Tubing, ASME SA249 TP304L ERW Tubes Supplier in Mumbai, India.

SS 304 / 304L Pipes & Tubes Chemical Composition

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni |

| SS 304 | 0.08 max | 2 max | 0.75 max | 0.045 max | 0.030 max | 18 – 20 | – | 8 – 11 |

| SS 304L | 0.035 max | 2.0 max | 1.0 max | 0.045 max | 0.03 max | 18 – 20 | – | 8 – 13 |

Mechanical Properties of SS 304 / 304L Pipes and Tubes

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.0 g/cm3 | 1400 °C (2550 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

Other Types of SS 304 and 304L Piping / Tubing

- ASTM A312 TP304/304L SS Square Pipe

- Stainless Steel 304/304L Dairy Pipe

- SS 304/304L Exhaust Pipe

- Stainless Steel 304/304L Hollow Pipe

- ASTM A312 TP304/304L Schedule 40 Pipe

- Stainless Steel 304/304L Sch 10 Pipe

- Stainless Steel 304 & 304L Seamless Pipe

- Stainless Steel 304/304L Industrial Pipes

- SS TP304/304L EP Pipes

- SS 304/304L Electric Resistance Welded Pipe

- SS 304/304L Electric Fusion Welded Pipes

- SS 304/304L Structural Steel Pipe

- SS 304/304L Instrumentation Tubing

- ASTM A213 TP304/304L High Pressure Tube

- SS 304/304L Electropolish Tubes

- Stainless Steel 304/304L Threaded Tube

- SS 304/304L Cold Rolled Coiled Tubing

- ASTM A269 TP304/304L Rectangular Tube

- Stainless Steel 304/304L Round Tubing

- SS 304/304L Sanitary Tubing

- SS 304/304L Heat Exchanger Tubes

- SS 304/304L U Shaped Tubing

- Stainless Steel 304/304L Coiled Tubing

- SS 304/304L Structural Steel Furnace Tubing

SS 304 / 304L Pipes & Tubes Popular Searches

Export Destinations For Stainless Steel 304 / 304L Pipes & Tubes

Domestic Supply For Stainless Steel 304 / 304L Pipes & Tubes

Bhopal, Sharjah, Hyderabad, Nagpur, Mumbai, Pune, Navi Mumbai, Vadodara, Surat, Ahmedabad, Chandigarh, Bengaluru, New Delhi, Rajkot, Jaipur, Ranchi, Kolkata, Ludhiana, Faridabad, Pimpri-Chinchwad, Gurgaon, Thiruvananthapuram, Dammam, Haryana, Noida, Nashik, Secunderabad, Chennai, Thane, Visakhapatnam, Baroda, Kanpur, Indore, Jamshedpur.

Material

World Wide Delivery